Reviewed by:Jos van den Nouwland – Product Manager for CG Drives & Automation

Soft starters are essential for controlling motor acceleration, minimizing mechanical stress, and improving energy efficiency—especially in pumps, compressors, conveyors, and HVAC systems. But when a soft starter fails, it can cause sudden shutdowns, costly repairs, or even motor damage. In this guide, we will show you the nine most common reasons for Emotron soft starters failure and how to troubleshoot them.

Why soft starter reliability matters

The reason why reliability matters is because, when a soft starter fails, you lose motor control. This can damage equipment, raise maintenance costs, and disrupt operations. Understanding soft starters impact on system reliability helps prevent most failures by identifying common causes and monitoring system behavior closely.

9 different causes of soft starter failure

1. Overheating due to poor ventilation

Blocked air vents, dust buildup, or high ambient temperatures can cause the internal electronics to overheat.

2. Incorrect sizing

Undersized starters fail to handle the load during startup, while oversized units may not offer optimal protection.

3. Supply phase loss or imbalance

Missing input phases or unstable voltage supply leads to erratic operation and fault codes like Phase loss or Voltage unbalance.

4. Rapid cycling (too frequent starts)

Frequent starts without cooldown time causes thermal stress and can damage SCRs or control boards.

5. Motor stall or mechanical overload

Blocked pumps or jammed compressors can trigger fault codes like F3 (stall detected).

6. Internal component aging or failure

Thyristors (SCRs), relays, and capacitors may degrade over time, particularly in harsh environments.

7. Incorrect parameter configuration

Wrong ramp times, current limits, or motor data entry can lead to slow starts, nuisance trips, or overcurrent errors.

8. Faulty bypass relay or wiring

Bypass relays that fail to engage correctly (e.g., fault Curr Unbal) may leave the soft starter vulnerable to overheating.

9. Power quality issues

Undervoltage (fault: Under voltage) and harmonics can disrupt timing signals and protection logic.

How to tell if your soft starter is going bad (Checklist)

Signs of failure include

- No motor response or delayed startup

- Frequent tripping with flashing LEDs

- Electrical smell or signs of overheating

- Irregular startup behavior (jerky or too fast)

- Audible relay clicking or lack of bypass engagement

Subscribe to our newsletter

Troubleshooting steps and root issues

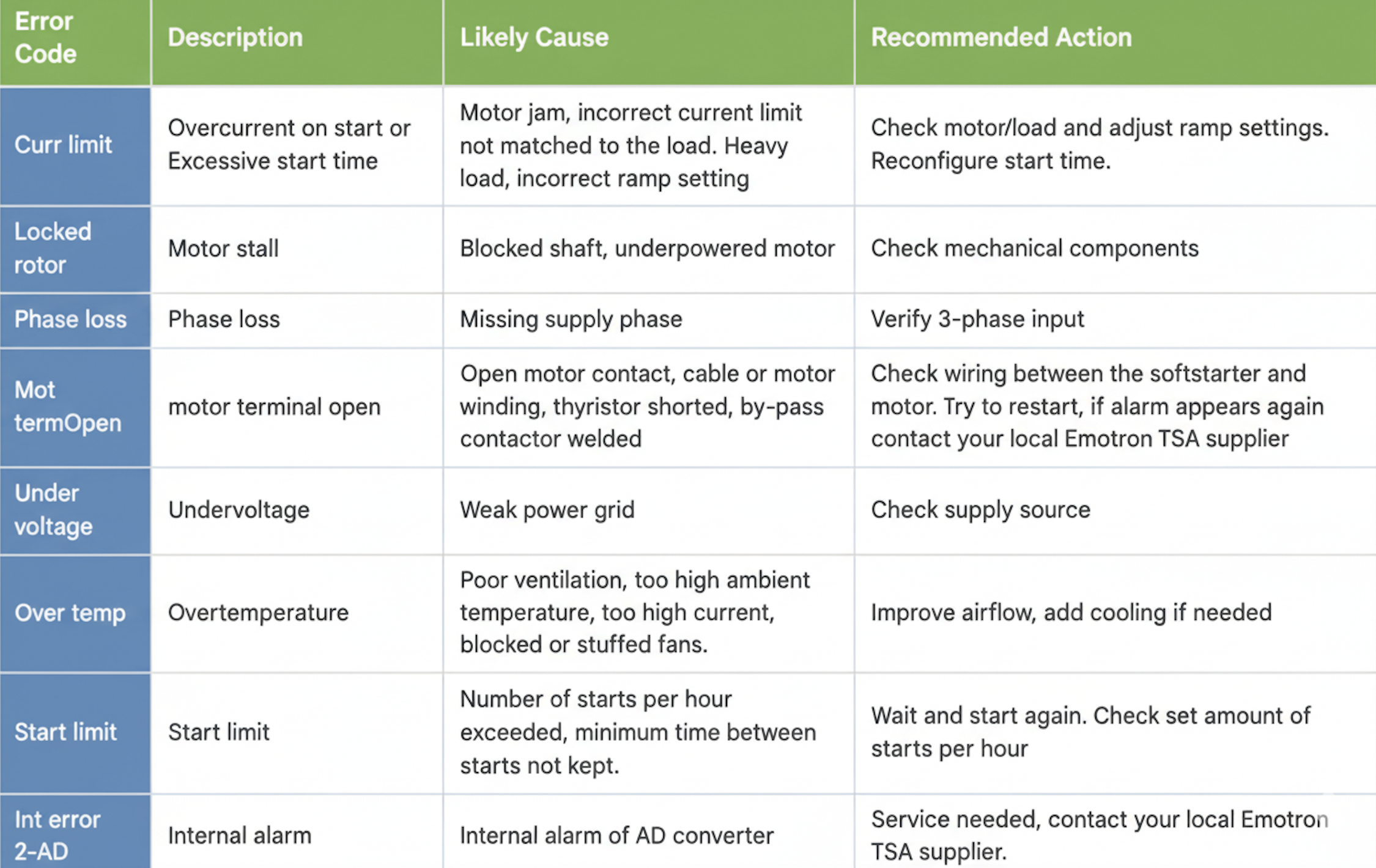

Step 1: Check the display or LED indicators for error codes and check with troubleshooting list in our instruction manual Chapter 11.

Step 2: Power cycle the unit and see if the fault resets.

Step 3: Inspect the starter for visible damage or dust buildup.

Step 4: Test voltage levels and verify wiring configuration.

Step 5: Confirm motor and application settings match real conditions.

Step 6: Log fault frequency to detect thermal issues or overload cycles.

When to reset, repair or replace

- Reset if the issue is transient (like an overload or undervoltage; check with troubleshooting list in instruction manual (Chapter 11).

- Repair if components like control boards or relays can be serviced (Emotron units offer replaceable modules).

- Replace if you detect SCR damage, repeated critical faults, or aging units beyond service life. When this occurs please contact the Emotron service and support department.

Emotron soft starter error codes and fixes

Common questions

Can soft starters damage compressors?

Only if misconfigured or mismatched. Emotron’s ramping curves are specifically optimized to avoid torque spikes.

How often should a soft starter be maintained?

Every 12 months or during annual service intervals. Look for dust buildup and check thermal paste/contacts.

Do I need a soft starter with a generator?

Yes. Soft starters reduce startup surges that could overload portable generators.

Can I repair an Emotron soft starter myself?

Basic cleaning and resets are fine, but internal board repairs should be left to authorized Emotron service technicians.

Final tips and free resources

If you’re experiencing issues, it’s a good idea to begin with a structured fault assessment. You can download the Soft Starter fault checklist (PDF) to guide your diagnostics and ensure no key step is missed. For more complex cases, consider scheduling a free troubleshooting session with an Emotron engineer—they can help you interpret error codes, verify settings, and get your system back on track.

Pro tip: A significant number of startup problems are caused by incorrect ramp settings. Always double-check that your ramp-up and ramp-down times are correctly configured based on the load type. Proper tuning at this stage can prevent unnecessary trips and ensure smoother operation.

If you’ve run through this soft starter checklist and your issues persist, the problem may lie with a different type of controller. This is common in complex systems where a soft starter is sometimes mistaken for a VFD (or vice-versa). For diagnostics on that equipment, please see our complete guide on VFD troubleshooting.