A Variable Frequency Drive (VFD), also called a frequency inverter, frequency converter, or AC drive, is an electronic device that regulates the speed and performance of an electric motor by adjusting the frequency and voltage of the power supplied to it. This enables smooth operation, improved energy efficiency, and enhanced control over motor functions.

How does a VFD work?

A VFD converts incoming AC power into an adjustable frequency and voltage source, enabling precise speed control for AC induction or PM motors. The motor speed is determined by the frequency of the applied power using the formula:

N = 120 x f / p = speed (rpm) where:

- N = Speed (RPM)

- f = Frequency (Hz)

- p = Number of motor poles

Stages of VFD Operation

- AC to DC Conversion (Rectification)

The Drive first converts AC voltage into DC voltage using a rectifier. - DC Voltage Regulation & Filtering

The DC voltage is filtered and smoothed using capacitors to provide a stable power source. - Pulse Width Modulation (PWM) & DC to AC Conversion

The regulated DC is changed back into adjustable AC. This is done using PWM-controlled semiconductor switches called IGBTs. These switches create a smooth sinusoidal motor current.

Common mistakes when using a frequency drive & how to avoid them

Although different VFDs offer great benefits, improper installation or usage can lead to inefficiencies or damage. Here are some of the most common mistakes and how to avoid them:

- Incorrect sizing – Ensure that the frequency drive is properly rated for the motor’s power, voltage, and load requirements.

- Poor cooling or ventilation – Overheating can shorten the lifespan.

- Always follow manufacturer guidelines for installation in well-ventilated environments.

- Ignoring harmonic distortion – If harmonics are not managed, they can lead to power quality issues. Use filters or AFE (Active Front End) drives where necessary.

- Improper wiring – Incorrect grounding and wiring configurations can lead to malfunctions and even damage the motor.

Understanding these common pitfalls can help maximize the efficiency and longevity of a Variable Frequency Drive system.

Maintenance & troubleshooting

Proper maintenance ensures that a VFD operates efficiently over its lifespan. Regular inspections and diagnostic measures can prevent costly downtime and equipment failures.

Key maintenance steps:

- Check cooling systems – Ensure that heat sinks and fans are clean and free from dust or debris.

- Inspect wiring and connections – Loose connections can cause erratic behavior or failure.

- Monitor operating conditions – Logging data on voltage, current, and temperature can help predict failures before they occur.

- Run firmware updates – Keeping the software up to date ensures that the Variable Frequency Drive operates at peak performance.

Troubleshooting common issues:

- Overheating – Check for blocked ventilation and ensure that the cooling fans are operational.

- Unexpected shutdowns – Look for overload conditions or faults in the motor wiring.

- Voltage fluctuations – Use line reactors or filters to manage inconsistencies in power supply.

By following these maintenance and troubleshooting guidelines, businesses can avoid costly repairs and ensure optimal performance of their VFDs.

Sign up for our newsletter to get expert insights on motor control and VFD selection!

Methods for choosing a variable frequency drive

Choosing the right VFD is crucial to ensure efficient motor performance, energy savings, and system longevity. Here are key factors to consider when making your choice:

Motor Specifications

- Ensure that the frequency inverter matches the motor’s power rating (HP/kW), voltage, and current requirements.

- Consider the motor type (induction, synchronous, PM motor) to choose the appropriate control method.

Application type

- Constant Torque Applications (e.g., conveyors, crushers) require frequency converters with high torque capacity.

- Variable Torque Applications (e.g., pumps, fans) benefit from energy-efficient VFDs that adjust power output dynamically.

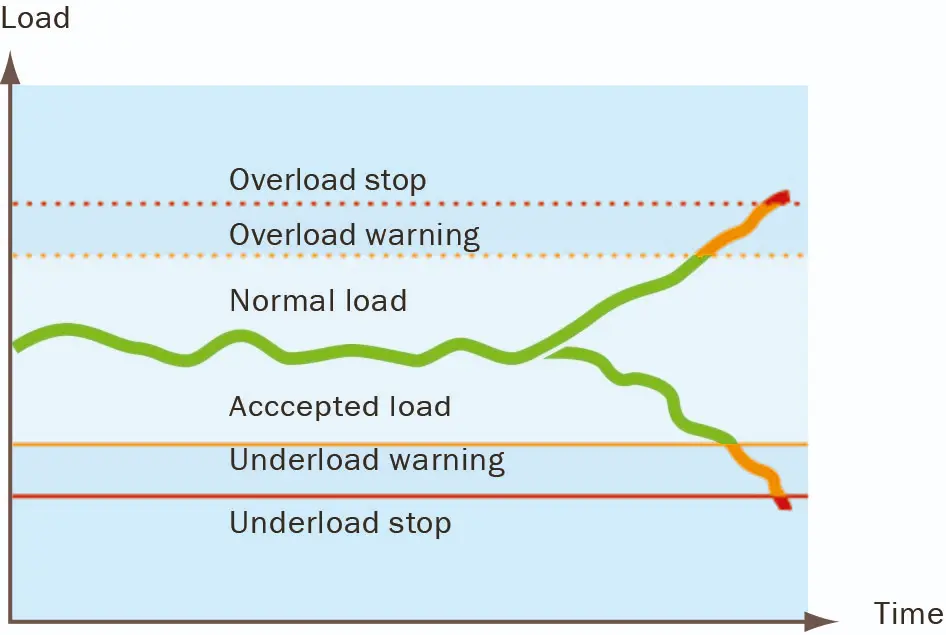

Load characteristics

- Evaluate starting torque needs, overload capacity, and acceleration/deceleration requirements.

- Choose an AC drive with vector control or Direct Torque Control (DTC) for high-performance loads.

Environmental conditions

- Select a frequency inverter with appropriate IP ratings for dusty, humid, or hazardous environments.

- Consider cooling requirements and whether forced ventilation or liquid cooling is needed.

Control & communication features

Ensure the AC drive supports communication protocols such as Modbus, Profibus, and Ethernet/IP if integration with a control system is required.

- Look for built-in monitoring functions like load detection, fault diagnostics, and energy monitoring.

Harmonics & power quality

- Use AFE (Active Front End) VFDs to reduce harmonic distortions and improve power quality.

- Consider using filters or reactors to comply with electrical standards and reduce interference.

Safety and protection features

- Ensure the VFD has overload protection, short-circuit protection, and thermal management.

- Look for braking choppers and emergency stop features if needed for applications like cranes and lifts.

By looking closely at these factors, you can choose the best VFD for your needs. This will help ensure good performance and lasting reliability.

Frequency inverter control methods

Different frequency converters use different control algorithms to regulate motor performance:

V/Hz (Volts per Hertz) control

- The simplest and most commonly used method.

- Maintains a constant voltage-to-frequency ratio.

- Best suited for pumps, fans, and other variable torque applications.

Vector control (Field-Oriented Control – FOC)

- Provides more precise speed and torque control.

- Uses motor feedback sensors to dynamically adjust voltage and current.

- Ideal for applications requiring high-performance speed and torque regulation.

Direct torque control (DTC)

Advanced control method used in Emotron VFX VFDs.

Reacts within 25 microseconds to changes in load and speed.

Suitable for cranes, crushers, conveyors, and other demanding constant torque applications.

Key components

Power semiconductors: IGBTs (Insulated Gate Bipolar Transistors)

- Act as high-speed electronic switches controlling the power supplied to the motor.

- Convert DC back to AC with a near-sinusoidal waveform.

Rectifier & inverter circuit

- Rectifier: Converts AC to DC.

- Inverter: Uses IGBTs to convert DC back to an adjustable AC output.

Control unit

- Regulates the output voltage, current, and frequency based on user input or automated signals.

Where can a VFD be used?

AC drives are widely used to save energy and control motor speed.

Common applications include:

Pumps & compressors

- Traditional systems regulate pressure/flow using valves.

- A Variable frequency drive optimizes speed, preventing energy waste and issues like water hammering.

- Emotron VFD detects dry running, leaks, blocked pipes, and cavitation.

Fans & blowers

- Running at optimal speed reduces energy costs.

- Prevents belt slipping, excessive wear, and filter blockages.

- Emotron drives offer power loss ride-through and spin start functions.

Cranes, lifts & conveyor belts

- Smooth and controlled starting/stopping to avoid jerky movements.

- Emotron frequency drives include a hoist load memory to prevent load drops.

- Brake chopper & Active Front End (AFE) technology ensure rapid, controlled braking.

Crushers, mixers, mills & band saws

- Handles peak loads & torque boosts for jammed equipment.

- Vector braking & load monitoring prevent damage and downtime.

- Automatically reverses rotation in case of overload.

Marine applications (Propulsion, Thrusters, Shaft Power Generation)

- Emotron AFE technology recycles shaft power.

- LCL filters minimize harmonic distortions for smooth operations.

Hybrid systems & battery backups

- Integrates power sources (batteries, generators) for efficiency.

- Emotron AFE & DCU technology ensures seamless energy flow.

Why choose an Emotron VFD?

- Energy-efficient design with advanced motor control.

- Modular & service-friendly architecture.

- Active Front End (AFE) regenerative braking for energy savings.

- Integrated load monitoring to protect equipment from failures.

- Robust build for harsh environments with PLC integration capabilities.

FAQ

What is the purpose of a VFD?

A VFD allows precise motor speed control, improving energy efficiency and performance while extending equipment lifespan.

Can a VFD be manually operated?

Yes, most VFDs can be manually controlled via built-in keypads or external interfaces.

What types of motors can be used with VFDs?

VFDs are primarily designed for AC induction motors but also work with Permanent Magnet (PM) motors.

Can a VFD destroy a motor?

Incorrect setup (e.g., excessive harmonics, voltage spikes) can damage motor windings, but a properly configured VFD extends motor life.

What is the difference between a VFD and a VSD?

A Variable Speed Drive (VSD) is a broader term covering different motor speed control methods, including VFDs, DC drives, and mechanical solutions.

Why should I use a VFD from Emotron?

A VFD from Emotron contains additional technology that allows you to further reduce your energy consumption, improve productivity and reduce the maintenance of your critical operations. The modular build makes the Emotron VFD flexible, cost efficient and service friendly.

What is the advantage of a variable frequency drive?

- Energy efficiency

- Precise speed control

- Lower maintenance and cost

- Less Noise and vibration

- Adaptability to various applications

What is the difference between PLC and VFD?

- A PLC is an automation controller that processes inputs and controls outputs in an industrial setting.

- A VFD is a motor controller that varies the speed of an electric motor for efficiency and performance.

In many industrial systems, PLCs and VFDs work well together – a PLC sends commands to the VFD to regulate motor speed based on real-time process requirements.

Conclusion

A Variable Frequency Drive (VFD) is a powerful tool for optimizing motor control, improving energy efficiency, and extending equipment lifespan. Throughout this article, we have explored how VFDs work, their key components, how to select the right VFD, and best practices for maintenance and troubleshooting.

By implementing the right VFD, businesses can achieve significant cost savings, enhanced system reliability, and improved operational flexibility. Whether it’s for pumps, fans, conveyors, cranes, or marine applications, selecting a well-matched and properly configured VFD is crucial for maximizing performance.

With Emotron VFDs, you gain access to advanced control algorithms, built-in load monitoring, and industry-leading efficiency.

If you’re looking to optimize your industrial processes, improve energy management, or need guidance in choosing the right drive for your application, contact us today to explore how Emotron can support your needs. Emotron VFDs offer advanced control, energy savings, and equipment protection across multiple industries. Whether for pumps, fans, cranes, or marine applications, an Emotron ensures reliability, efficiency, and seamless motor control.